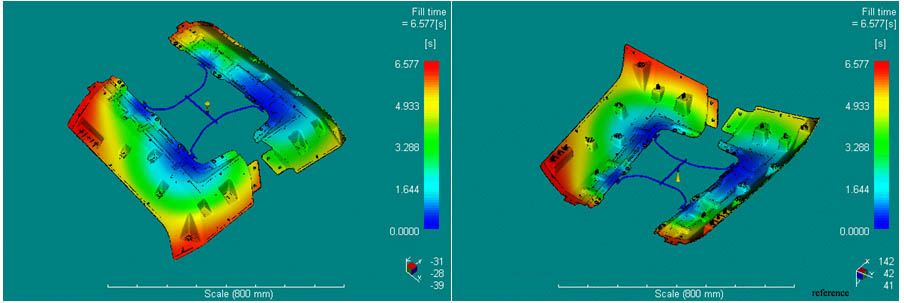

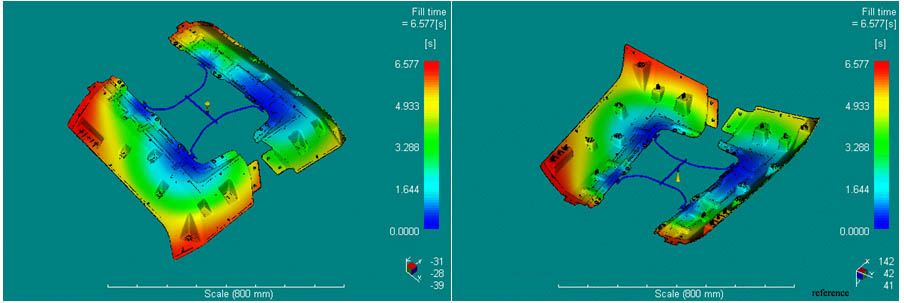

Flow Analysis

FLOW ANALYSIS:

Our team analyzes parts designed Plastic or Rubber to be injection molded to help select and specify materials and mold tooling

and press parameters in order to optimize cycle time,

part fill, strength and cosmetic appearance and, to fix the following points:

- Predict the flow front pattern to aid in part design and gate placement to optimize cavity filling.

- Calculate the conversion (extern of cure) versus time at any location within the mold.

- Determine injection pressure and clamp force requirements for proper molding machine selection.

- Display injection pressure at any point within the cavity at any time during filling.

- Graphically display the temperature change as a result of the reaction kinetics inside the mold at any time.

- Detect short shots due to pre-gelatin conditions.

- Accurately identify weld lines based on part design and gate placement.

- Accurately identify air traps for proper mold venting.